Concrete GPR

GPR Services & Technology

NDT (non-destructive testing) is done with a technique called GPR, which stands for “Ground Penetrating Radar”. GPR equipment transmits and receives electromagnetic waves into the ground subsurface or other material and detects interfaces between differing materials.

The interfaces between differing materials are identified by changes which occur in the electromagnetic waves. These changes can be voids, reinforcing bars, underground utilities (metal or plastic), conduits, or various other items. The antenna transmits and receives a high-frequency electromagnetic impulse into the study material and records the travel time and amplitude of these impulses.

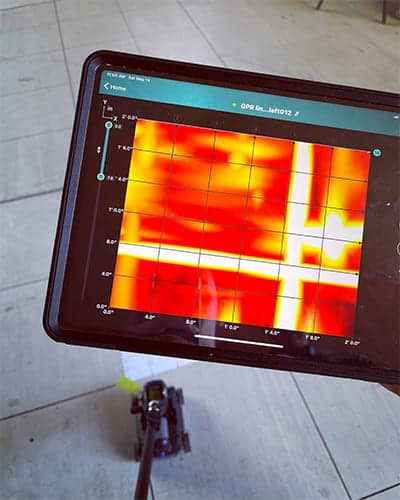

The GPR system records these deflections and digitally process them. Data output is typically read and interpreted by the use of a color video screen. The data can also be digitally recorded and downloaded to a computer for further processing and interpretation.

Benefits of using GPR

- GPR is a real-time NDT technique that quickly locates the position of post tension cables, rebar, and electrical conduits embedded in concretes.

- By locating it eliminating dangers associated with cutting or drilling and the high costs required for their repair if cut or damaged.

- Accurate target location within a concrete slab on-grade, wall, or supported slab can be achieved more quickly, safely, and economically with GPR services instead of other existing techniques.

- GPR is a safer and less disruptive than X-Raying.

- GPR equipment is safe to use around people without any safety constraints or setup requirements. Because of these features, interruption of operations can be eliminated or minimised.